Cost-Effective and Eco-Friendly Transformer Upkeep With Regenerated Oil

The assimilation of regrowed oil in transformer upkeep offers an engaging approach for companies looking for to enhance both cost-efficiency and eco-friendliness. By making use of oil that maintains performance criteria similar to virgin options, businesses can considerably reduce operational expenses while concurrently minimizing their environmental effect. This strategy not just attends to the monetary problems related to waste disposal and regular oil modifications but likewise contributes to more comprehensive sustainability efforts. Nonetheless, the effects of this change expand past immediate advantages; recognizing the full extent of its advantages requires a better evaluation of the principles and practices included.

Recognizing Regenerated Oil

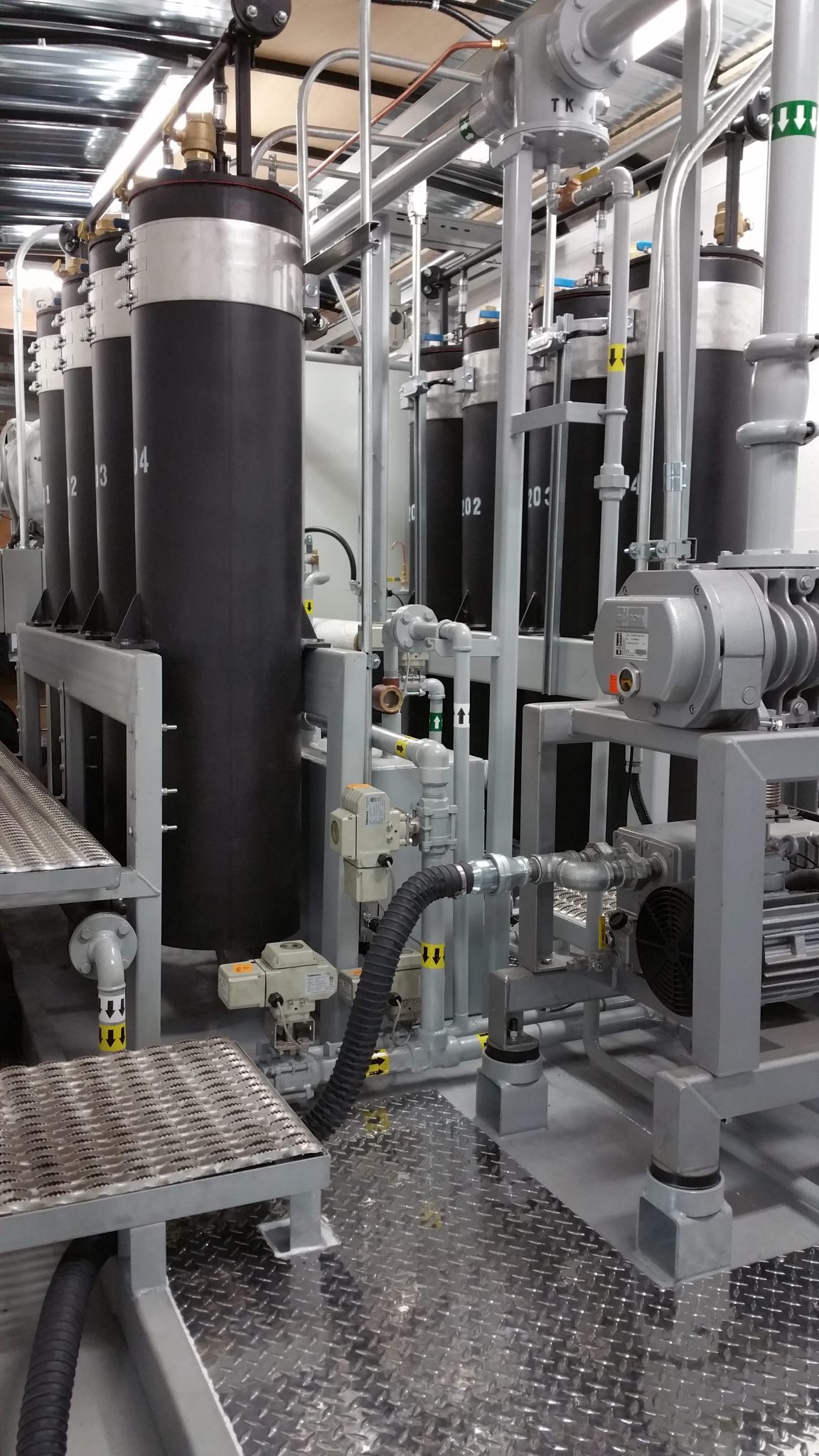

Regenerated oil, frequently referred to as re-refined oil, is an essential part in the maintenance of transformers, providing both environmental and economic benefits. This oil is stemmed from used mineral oils that have undertaken a detailed purification process, properly removing pollutants and bring back the oil to a quality equivalent to virgin oil. The regeneration procedure commonly entails several phases, consisting of physical splitting up, chemical therapy, and filtration, making certain that impurities such as sludge, water, and hefty metals are eliminated.

The utilization of regrowed oil in transformers is important for enhancing performance and expanding devices life expectancy. High-grade re-refined oil preserves its dielectric homes, ensuring effective insulation and avoiding electric failures. Furthermore, it possesses exceptional thermal conductivity, which aids in handling the functional temperature levels of transformers, eventually boosting their reliability and efficiency.

Additionally, embracing regenerated oil not just supports economical maintenance techniques however additionally reduces the need for new oil production, thereby conserving natural resources. Transitioning to re-refined oil is a smart choice for companies intending to maintain high operational standards while simultaneously managing budget plan restrictions. Comprehending the residential or commercial properties and advantages of regenerated oil is important for informed decision-making in transformer maintenance methods.

Ecological Advantages

Making use of regenerated oil in transformer upkeep uses substantial environmental benefits that contribute to lasting practices within the energy industry. Among the primary advantages is the reduction of waste oil disposal, as regenerated oil is originated from the recycling of made use of transformer oil, significantly decreasing the volume of contaminated materials generated. This procedure assists alleviate the ecological threats associated with inappropriate disposal methods, which can lead to dirt and water contamination.

Additionally, the regeneration procedure preserves all-natural sources by lessening the need for new base oil manufacturing - Transformer Oil Regeneration Plant. This conservation initiative not just decreases the removal effect on ecological communities however likewise reduces the carbon footprint associated with oil production. By adopting regrowed oil, companies can enhance their commitment to environmental stewardship and align with international sustainability objectives

Moreover, making use of regrowed oil enhances the overall effectiveness of transformers, causing minimized energy losses and reduced greenhouse gas discharges. As the energy sector increasingly encounters stress to decrease its ecological influence, accepting regenerated oil represents an aggressive approach to attaining both operational and ecological purposes. In summary, the environmental benefits of utilizing regenerated oil are diverse, advertising a healthier earth while supporting the power market's change in the direction of sustainability.

Expense Cost Savings and Performance

Making use of regenerated oil in transformer upkeep can result in considerable cost savings and boosted operational effectiveness for power firms. Restored oil, produced with innovative purification processes, offers equivalent efficiency to brand-new oil at a fraction of the price. By recycling oil that would certainly otherwise be discarded, companies can minimize their investing in costs while decreasing waste disposal costs.

Furthermore, the extended life cycle of restored oil translates to lowered frequency of oil adjustments, causing reduced labor expenses and minimized downtime for upkeep tasks. Transformer Oil Regeneration. This not just improves operational effectiveness but additionally permits for a more streamlined maintenance schedule, making it possible for business to allocate sources much more properly

In enhancement, the use of regenerated oil can cause reduced insurance premiums as a result of its environmentally pleasant profile. As power companies deal with raising examination regarding their environmental effect, embracing sustainable practices such as using restored oil can strengthen their reputation and potentially draw in financial investment.

Eventually, the assimilation of restored oil right into transformer upkeep methods offers a critical opportunity for energy firms to attain considerable expense savings while promoting functional performance, thereby aligning financial performance with ecological responsibility.

Contrast With Traditional Oils

While conventional oils have long been the requirement in transformer upkeep, a detailed comparison reveals that regenerated oils supply several advantages that enhance performance and sustainability. Conventional mineral oils, while reliable, commonly position ecological dangers, such as contamination and disposal issues. In contrast, regenerated oils are stemmed from recycled materials, considerably minimizing their eco-friendly footprint.

They commonly show remarkable oxidative security, which equates to longer solution life and reduced frequency of oil changes. This particular not only boosts transformer efficiency however additionally minimizes downtime and maintenance costs.

In addition, regenerated oils offer excellent dielectric residential properties, making certain reliable electrical insulation. This high quality is essential in preserving transformer performance under differing operational problems. Making use of regenerated oils also lines up with worldwide sustainability objectives, interesting companies committed to decreasing their carbon footprint. Generally, the benefits of regenerated oils over conventional oils highlight their prospective to transform transformer maintenance techniques, supplying an extra effective and responsible alternative.

Implementation in Maintenance Practices

When the analysis is complete, a customized plan for transitioning to restored oil must be established, thinking about variables such as compatibility with existing products and functional problems. Training for upkeep employees is crucial, as they must understand the distinct buildings of regenerated oils and exactly how to manage their application successfully.

Implementing Reclaimed Transformer Oil an extensive monitoring program will certainly facilitate the evaluation of performance metrics post-implementation, ensuring the regrowed oil meets the required functional criteria. Transformer Oil Regeneration. In addition, developing a normal maintenance timetable will certainly assist in recognizing potential problems early and enable prompt restorative actions

Verdict

In conclusion, the fostering of regrowed oil for transformer upkeep offers a viable service that straightens economic benefits with ecological sustainability. By minimizing expenses related to oil modifications and garbage disposal, while concurrently prolonging the life expectancy of equipment, companies can boost operational effectiveness. The shift to regenerated oil not just alleviates environmental influences however additionally sustains more comprehensive sustainability goals, making it a sensible selection for modern-day upkeep practices in the power market.

Restored oil, often referred to as re-refined oil, is a critical element in the maintenance of transformers, providing both economic and ecological advantages. This oil is derived from made use of mineral oils that have gone through an extensive filtration process, properly removing impurities and bring back the oil to a quality similar to virgin oil.Moreover, adopting restored oil not only supports cost-efficient maintenance techniques yet additionally reduces the need for brand-new oil production, thus saving all-natural resources. One of the primary advantages is the decrease of waste oil disposal, as regenerated oil is acquired from the recycling of made use of transformer oil, dramatically reducing the quantity of harmful waste created. Restored oil, generated through sophisticated purification processes, provides similar performance to new oil at a fraction of the price.